In order to distinguish the hot rolled stainless steel and cold rolled stainless steel, the first step is to follow Inox Dai Duong’s research of the stainless steel producing process as below.

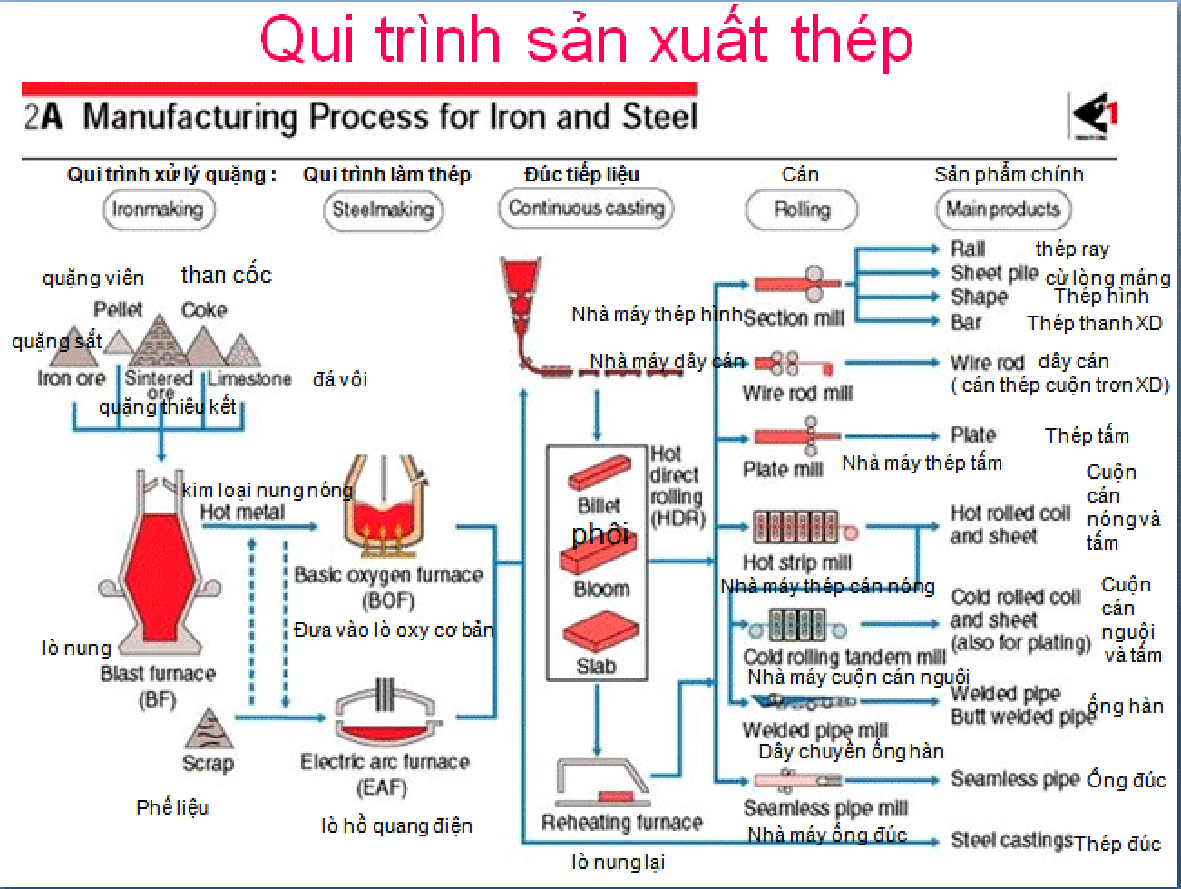

At the early beginning of the process, it is the iron ore and scrap, then the finished process products are stainless steel, or differently called Inox. Moreover, have a look at the description chart of the manufacturing process for iron and steel:

Nội dung chính

Manufacturing Process for Iron and Steel

The stage 1: Iron making

In this stage, the income raw materials are pellet, iron ore, coke, sintered ore, lime stone being transported to blast furnace.

In the case of scrap, it is also heated with the approriate temperature to become hot metal

The stage 2 : The steel making

The hot metal made in the first stage is directed to the basic oxygen furnace or electric arc furnace. Here, hot metals are processed, separated impurities and created correlations between chemical components, according to that for deciding what kind of steel to produce or what type of steel grade. For example, the steel will be used to roll the bar SD390 the chemical components will be adjusted right at this stage to give the steel grade SD390.

The stage 3: the continuos casting

Then the hot steel from stage 2 is moved to :

Steel casting: producing other steel items.

The furnace casting ingot:

Here, it’s made 3 kinds of billet:

The billet bars are available for the sizes like 100×100, 125×125, 150×150 and length per piece 6-9- 12 m as well as usually being rolled to construction steel coil or strip steel.

The slab billet is often used to make the hot rolled coil and sheet or the cold rolled coil and sheet. The bloom billet is taken a place of the two above billets.

After that, the billets can be formed into hot or cold direct rolling.

The hot direct rolling is illustrated that the billet is still remained the heated form after billet processing in order to produce in stage 4

And the reverse form of the billet above is transported to other factories to reheat furnace, then passed to make products in the stage 4.

The stage 4: rolling

The billets are transported to other section mills in order of making main products.

Putting billet into a steel mill (Section mill) to roll out steel products as follows: Rail (steel rail); Sheet pile (steel sheet); Shape (shape steel of all kinds); Bar (steel bar construction).

Putting billets into hot rolled mill (Hot Strip mill), billets will be rolled into hot rolled coil (Hot roll coil-HRC) or steel cutting plate (cut immediately the stock roll and bales-Baotou Goods). In the process of rolling out high-temperature hot rolled coil steel (eg 780oC) if you want to roll out cold rolled steel coil (Cold roll coil-CRC), reduce that temperature to the right temperature (eg: 480oC) and continue rolling down the thickness.

Thus, right at this stage, it produces cold rolled steel and hot rolled steel.

Currently, re-rolling mills in Vietnam are using hot rolled steel billet: (1.75-5.0 mm) then put it into a kiln up to the appropriate temperature (VD 480oC) to reduce the rolling Thickened cold rolled steel coil.

Putting billets into cast steel pipe mills (Seamless pipe mill) to produce seamless steel pipes.

Above, is the process of producing steel products. So we can understand how cold rolled steel, hot rolled steel produced. Here we can see some pictures to be able to distinguish cold rolled steel and hot rolled steel coil.

| Cold rolled steel coil | Hot rolled steel coil | |

| Available thickness | 0.15mm-2mm | More than 0.9mm |

| Surface finish | Bright white, high gloss. | Dark green, dark characteristic |

| Frontier | Usually cut straight and sharp edges | Two rolls are often rounded, rough, rust-colored when left for long. |

| Preservation | Cold rolled goods usually have packaging and put in the house due to quickly rusted surface | Hot rolled steel can be left outdoors for a long time and does not require storage. |

Source: Phân Biệt Inox Cán Nóng và Inox Cán Nguội

CÔNG TY CỔ PHẦN QUỐC TẾ ĐẠI DƯƠNG O S S

Inox Đại Dương cam kết cung cấp vật tư inox đạt chuẩn – đúng nguồn gốc – đúng chất lượng, giúp doanh nghiệp yên tâm sản xuất và nâng cao uy tín thương hiệu.

Nếu bạn cần hỗ trợ về sản phẩm hoặc báo giá nhanh, vui lòng liên hệ với chúng tôi qua thông tin dưới đây:

Xem chính sách nội dung