Steel is the most commonly used material in all fields of life today, especially in factories and construction sites. Steel has many types and each type has different uses, in this article with Inox OSS Dai Duong learn the popular types of steel, their applications and how to classify them.

Nội dung chính

What is steel?

Steel is an alloy of iron and carbon with a carbon ratio of 0.02% to 2.14% by weight and some other elements. Steel is metallic gray, hard, flexible and elastic, so it is malleable and easy to work with. Different proportions of substances in steel alloys will lead to different properties of hardness, elasticity and tensile strength.

Because it is an alloy of iron, steel has very high electrical conductivity, thermal conductivity and melting point. The density of steel is from 7.8 to 7.85 g/cm3.

How to classify steel types?

Manufacturers, traders as well as consumers often classify steel based on specific factors such as elemental composition, quality or intended use.

Classification by intended use:

- Structural steel: used in construction, mechanical industry, manufacturing and assembling machinery. They have good bearing capacity, toughness. Because of the specificity of this use, the steel has high strength and can withstand a large load.

- Tool steel: as the name suggests, this steel is used to make molds, tools, stamping dies, sharpeners of all kinds, household and civil tools. Steel is usually durable, good bearing, has high hardness and especially good oxidation resistance.

- Steel with physical (magnetic) properties: some electrical engineering products or components often require steel to have specific physical properties such as expansion coefficients or magnetism.

- Steel with chemical properties: steel with high temperature resistance, effective anti-corrosion (stainless steel).

Related posts:

Classification by chemical:

Based on chemical criteria, steel can be classified into carbon steel and alloy steel. In there:

Carbon steel with low, medium and high carbon content in steel will lead to characteristic changes in properties such as ductility, brittleness, bearing capacity, etc. This type of steel also accounts for a large number, up to nearly 90 % of total steel.

In addition to the percentage of carbon, steel is also classified based on the ratio of components in steel such as manganese, copper, chromium, aluminum, nickel …

| Steel | Level | Characteristics | Standards |

|

Carbon Steel |

Low carbon | Average carbon content ≤0,25% | Russia Standards ГОСТ 380-71 ГОСТ 1050-75 |

| Medium carbon | Average carbon content from 0,25% to 0,6% | ||

| High carbon | Average carbon content from 0,6% to 2% | ||

| Alloy Steel | Low alloy | Content of other metals <2,5% | Russia Standards ГОСТ 4543-71 ГОСТ 5632-72 ГОСТ 14959-79 |

| Medium alloy | Content of other metals from 2,5% to 10% | ||

| High alloy | Content of other metals >10% |

Classification by quality factor:

Steel, in addition to the main elements such as iron, carbon, other elements will also contain some impurities such as sulfur or phosphorus. The lower the percentage of this impurity in the steel, the better the steel is considered.

The quality level is rated according to the following table scale:

| Impurities Ratio | Medium quality steel | Good quality steel | High quality steel | Special quality steel |

| % | 0,06% S

0,07% P |

0,035% S

0,035% P |

0,025% S

0,025% P |

0,015% S

0,025% P |

Classification by antioxidant capacity:

The ratio of elements is different, resulting in different antioxidant capacity. Therefore, people also classify steel based on this special ability. In there:

| Steel type | Killed (l) | Semi-killed (n) | Rimmed (s) |

| Oxidation level | Complete oxidation | Oxidation level is between Killed and Rimmed steel | Poor oxidation |

| Characteristics | Not easy to cold stamp

Hard, durable No air bubbles when casting |

Properties in the middle of killed and rimmed steel | Easy to cold stamp

Soft, supple Easy to produce air bubbles when casting |

The most popular types of steel today

There are many types of steel, classified according to the above methods. However, at present, the most popular types of structural steel on the market are plates, shapes, boxes, bars, coils, etc., suitable for applications in many different fields.

Steel plate

Steel plate is processed by a complex process from the starting material, laminated into sheets / pieces with different sizes, divided into hot rolled steel and cold rolled steel. In addition, steel plate is also available in coil form to help manufacturers save costs when producing in large quantities.

Advantages:

- Durable

- Good bearing capacity

- Easy to store and maintain. Note: cold rolled steel needs to avoid rain water and chemical substances.

- The applicability is very high because there are many specifications (width, thickness, length to meters).

- High advantages when transporting: the flat surface should limit bending, warping and distortion compared to other steels.

Applications: shipbuilding, civil, factory furniture, roofing, vehicles (trucks, vans, containers …) processing product details with flat and wide surfaces such as tables, chairs, cabinet…

Steel pipe

Steel pipes are cylindrical but hollow, round, square, rectangular, oval… Wall thickness from 0.7mm to 6.35mm, diameter from 12.7mm to 219.1mm. The surface can be further plated to increase corrosion resistance.

Regarding processing, steel pipes are also divided into galvanized steel pipes, welded steel pipes (twist, straight, high-rise), carbon steel pipes …

Advantages:

- Durable.

- Withstand force impact and heat resistance

- Easy to install

Applications: scaffolding, pre-engineered steel buildings, foundation structures, light poles, pipes and drainage of water or oil, frames of vehicles, interior and exterior decoration.

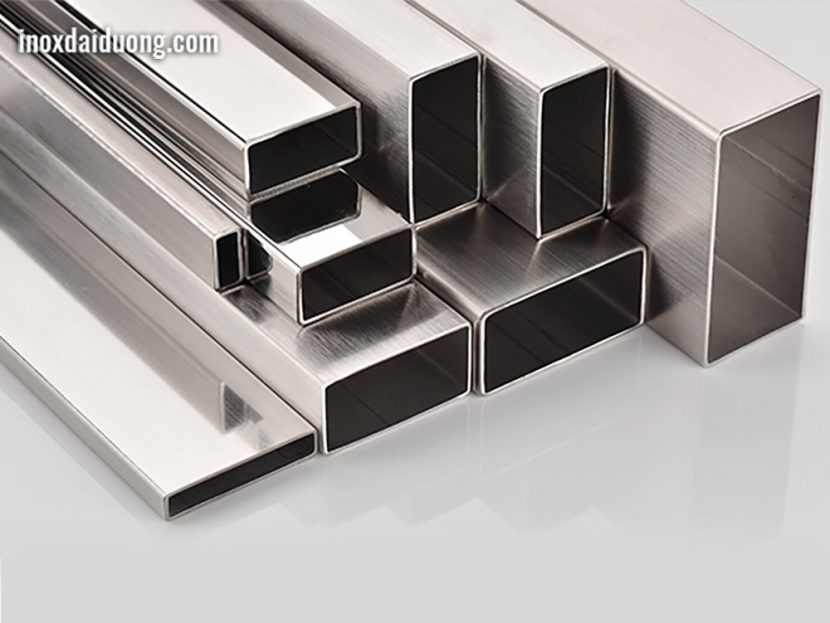

Steel Box

Steel box is formed into boxed shapes and hollow. The most common are square and rectangular shapes. The wall thickness of the box is from 0.7 to 5.1mm and 6,000m long.

Depending on the purpose and environmental conditions, the black steel box is used under normal conditions, not in direct contact with acids and salts or sea water. In case of more severe conditions such as coastal or chemical exposure, galvanized steel is preferred. The outer zinc coating protects the inner steel surface from oxidation.

(Stainless steel pipe and box products are produced by O S S Dai Duong factory)

Applications:

- Black steel box is widely used in construction projects, factories, and civil products.

- Galvanized steel has the same application but in coastal environments, warehouses and chemical plants.

Steel Structural Section

Currently, various types of steel are popular such as H-shaped steel, I-shaped steel, V-shaped steel, U-shaped steel, angle … These steels are rich in shape and size so they are suitable for many industrial fields, especially construction industry.

In addition, the advantage of steel structural section is also known for its solid, durable structure that can withstand loads and vibrations.

Applications: in construction, equipment, machinery, prefabricated houses, bridges, roads, vehicle frames, interior-exterior, towers and electric poles…

Construction steel

There are specific types of steel used a lot in the construction industry so they are collectively called construction steel. Thanks to features such as diverse types and sizes, it is suitable for many items and product details in large and small projects.

- Round steel bar: there are 2 types: plain and rebar steel. Plain steel bar with diameter from Ø14 – Ø25, length 12m, with elongation and ductility, flexible to bend. Rebar, also known as concrete reinforcement with diameter from Ø10 to Ø32, is used to strengthen the pillars in the construction.

- Wire rob steel: coiled steel wire with weight from 200kg to 460kg. Small diameter, thin, smooth surface so wire rod steel is used to pull wire in construction works.

- Purlins:

-

- For large-scale projects (factories, shipbuilding, bridges, roads, construction items of walls, roofs, support plates …) the materials used are industrial steel, also known as purlins because they have outstanding durability, sturdy, aesthetic and does not warp under force.

- Hot-rolled purlins, processed by advanced technology, also have a certain degree of fire resistance, helping the workshop to limit and minimize the consequences of fire. Purlin has 2 types: black steel and galvanized purlin. In which, there are 2 popular shapes: C and Z.

Above is the useful information that O S S Dai Duong has gathered all about today’s popular steels. Hope the article will help all the readers.

Kindly follow O S S Dai Duong fanpage to receive the latest information!

Editorial board: O S S Dai Duong